BEEFY

I Smile when Gasoline Can Freeze

- Location

- Prince George, BC, Canada

I like it

Uh-oh, what have you heard?Kinda curious how this pans out. I have heard mixed things about high steer and calmini kit

My Instagram account has reached a high mark as one of the posts of my truck made it into the Ruff Stuff "story" and was called "AWESOME" this morning;

Great video, and most excellent choice of music.Bah, I forgot to post this is an awesome vid my buddy Justin made from footage he shot at a run at Rausch back in October 2019. Check out Dennis’ way cool Tracker and Dave’s unstoppable Hydro Steer 1st Gen…

Turn up the volume and enjoy:

View: https://vimeo.com/380602209

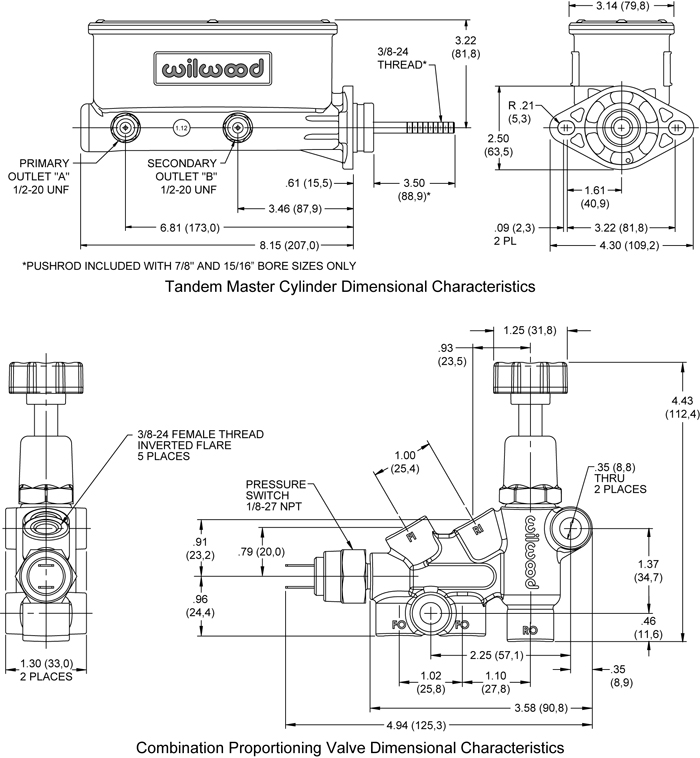

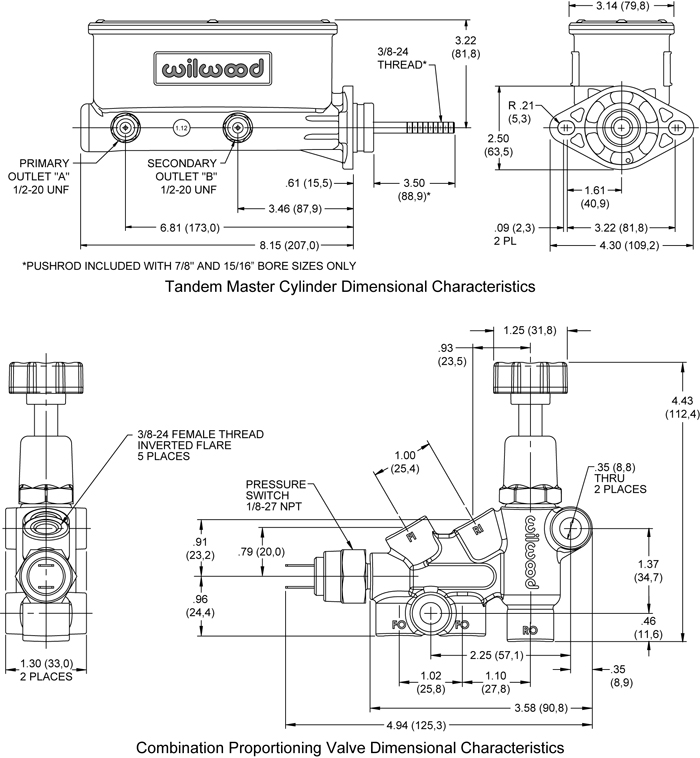

This is a Wilwood Aluminum Tandem Chamber Master Cylinder with the Combination Proportioning Valve and Wilwood ten pound residual pressure valve. You can access the specs by clicking the links.

I went with this MC on Dave’s (http://bandit4x4.com/) recommendation. He has one in his truck and said he’d help install it (basically install it while I handed him tools).

It is a direct swap; take out the OEM MC, the pin part of the output rod length adjuster and ABS module. Bench bleed the Wilwood MC, bolt it to the brake booster with the OEM hardware, connect the fluid lines, connect the pressure valve, bleed the system.

This MC kit ain’t cheap but you get what you pay for, again, check the specs HERE. Considering that lack of specific info on others SAS brake setups on 1st Gen SAS’d trucks I could find, that I knew it would fit, that Dave was going to install it and that I would learn how to do something it was kinda a no brainer.

OEM out, residual pressure valve installed.

MC installed;

Bleeding a brake system is always a PITA even with speed bleeders but after a few times around we got it done.

The brakes felt spongy with the OEM MC even after the ABS delete but would stop the truck. I took it to the NEXTerra B2SR17 and they held fine on the trail. The system just didn’t instill any kind of confidence.

With the Wilwood installed I was able to stop the truck in about 30 feet from 30mph leaving a skid mark. On the drive back to Brooklyn the brakes felt stronger than the OEM system pre SAS. I’m happy, money and time well spent.

Thanks Dave!

I had taken out the ABS and ran straight lines to see if I could run the OEM MC before I put in the Wilwood MC. It helped a little but not enough. So the ABS was already out before I put the Wilwood in.

The write up is really all I did. It’s always a pain working on a brake system without getting brake fluid all over. Draining, filling and bleeding is a tedious sometimes frustrating exercise and ya really need at least one extra guy…I had two.

We used a standard roll of copper brake line and common fittings from NAPA. Used a tube cutter and flare kit.

Even with the three of us it took a day to figure out what to do, chase down leaks on sloppy flares and bleed the MF’er.

I don’t know if you’ve ever bled a system that is new or been drained but it sucks.

I’ll try and get more pictures this weekend. If there is a specific angle you want let me know. I can try and find the receipts for the line and fittings if you want the exact numbers.

I would guess you could run the ABS with it but never seen any OEM MC replaced on an Xterra with the ABS.

Why are you changing the MC?

The Wilwood is Aluminum. I no longer have the OEM MC.

The Wilwood kit that includes Proportioning Valve, mounting bracket, fluid tubes and mounting hardware kit on my truck;

Specs including a bench bleed vid HERE

Specs on the Residual Pressure Valve used to compensate for return spring tension in the rear drums HERE.

I’m the last MF’r to tell anyone not to do a mod but I want to be honest and say I don’t know if swapping in this MC will help you.

I put it in because the OEM MC, though big enough to push an ample amount of fluid to my modern and beefy 2001 multi piston OEM caliper, could not adequately feed the large out dated single piston ’89 caliper on my d44.

The only gain I was looking for with the Wilwood MC was to move more fluid.

Unless you’re currently pushing your brake pedal to the floor to try and bring your truck to a stop, I’d rethink this move.

I would think that, theoretically, you could run the ABS with the Wilwood but again, why change the MC?

Are you running steel lines throughout your system?

That’s a nice looking shaft.

Are you talking about the trail 16 hill climb?