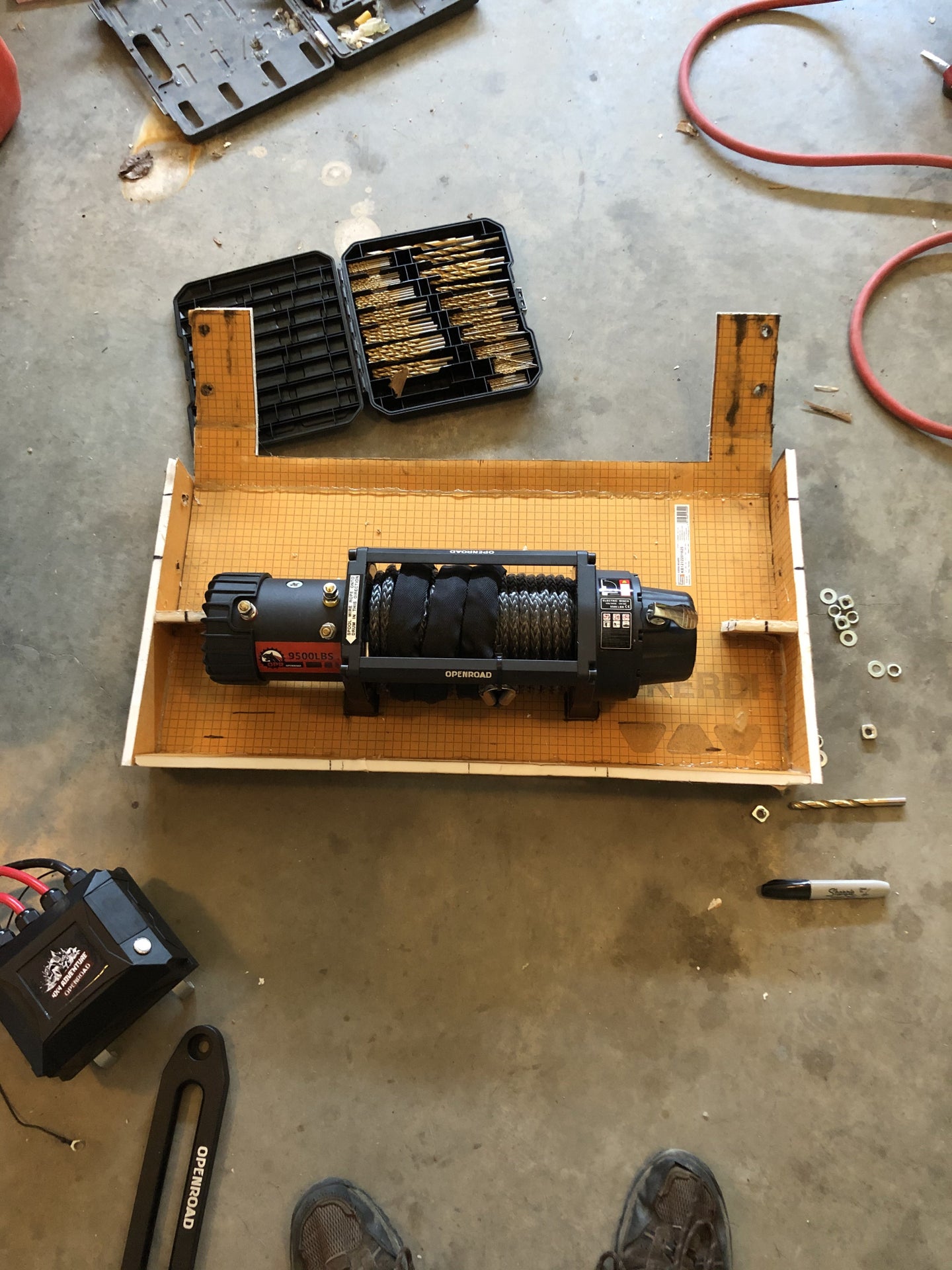

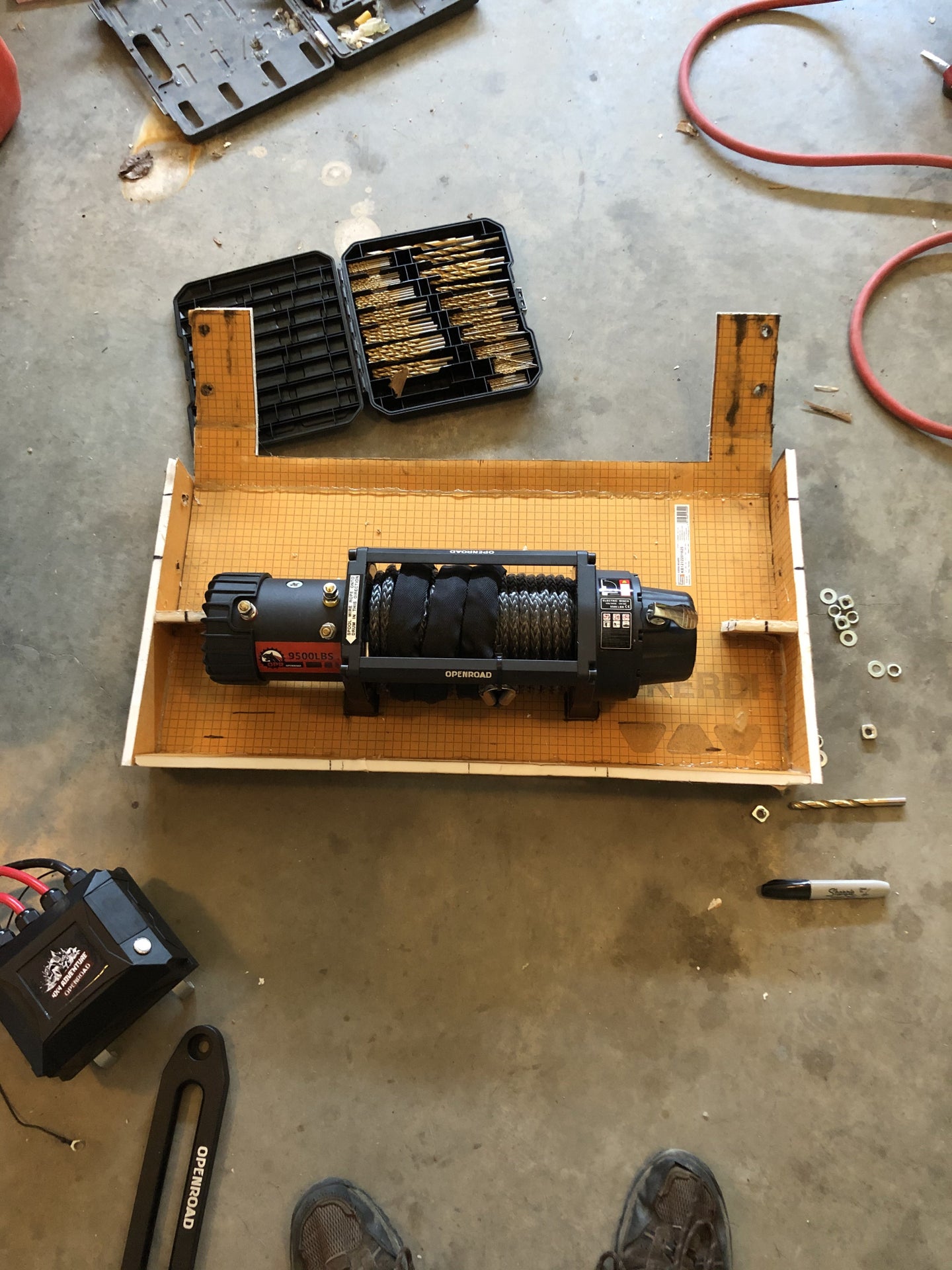

There’s not a ton affordable options for mounting a winch to a first gen xterra. It’s kind of a pain butt trying to find an option. A winch bumper seems to be minimum $800-1000 Canadian. There are a couple of options where you weld the bumper yourself and the kit is about $600. I decided to design a winch mount in the hopes that I could keep the price at a fabrication shop under $400. I made the mock up out of a stiff foam core board. And bought a open road winch, so that I could get the sizing right. The design has 10 bolts in the frame all 8 threaded holes and 2 unthreaded. It also acts as protection for the radiator and air conditioning condenser.

I didn’t have to drill any holes in the frame. I designed it in a way that it would bend underneath the frame horns and terminate at the factory tow hook mounting holes, working out the angles that the material needed to be bent too was difficult.

the idea is that most of the pressure from winching is directed up into the frame, instead of it being mounted on top of the frame horns. This also makes the design slightly more compact and lightweight.

I mentioned getting it fabricated at a shop. That didn’t work out, the shops I brought the design too took forever to get me a price. I assume they didn’t really want to do it; I don’t know if it was worth it to them to make it since I had done all the design work. But those are the fab shops in my area. I’m sure in different areas some shops might do it no problem. Almost every shop asked me to leave the template with them to get a price. Only two shops ever gave me a price, 600 dollars but those were aluminum specialty shops. And I wanted it made out of steel so they told me they would have to send it out to get it fabbed by a steel shop. So I went directly to steel shops, the others ended up taking half a week before they even took a look at it, and I would just ask for the template back because it was taking too long. The odd thing was the final shop I took it too, the guy took my template out of the shop for some reason, and it was like pulling teeth trying to get it back. I didn’t want to have to make another one. I decided to buy a welder and steel and fabricate it myself. The welder cost around $200 canadian for a 80 amp flux core welder From crappy tire. I have access to grinders drills bits wire and basic things to work on vehicles. Let’s say $150 in new tools, I used about $150 in steel 1/4 inch. I had never welded before. But I figured with enough research I would be able to. My welds aren’t pretty and the jury is still out on wether or not it’s strong enough we’ll see how it holds up. I bent the steel by cutting it over halfway, then locking a crescent wrench over it and levering the steel up. Then welded the cut side.

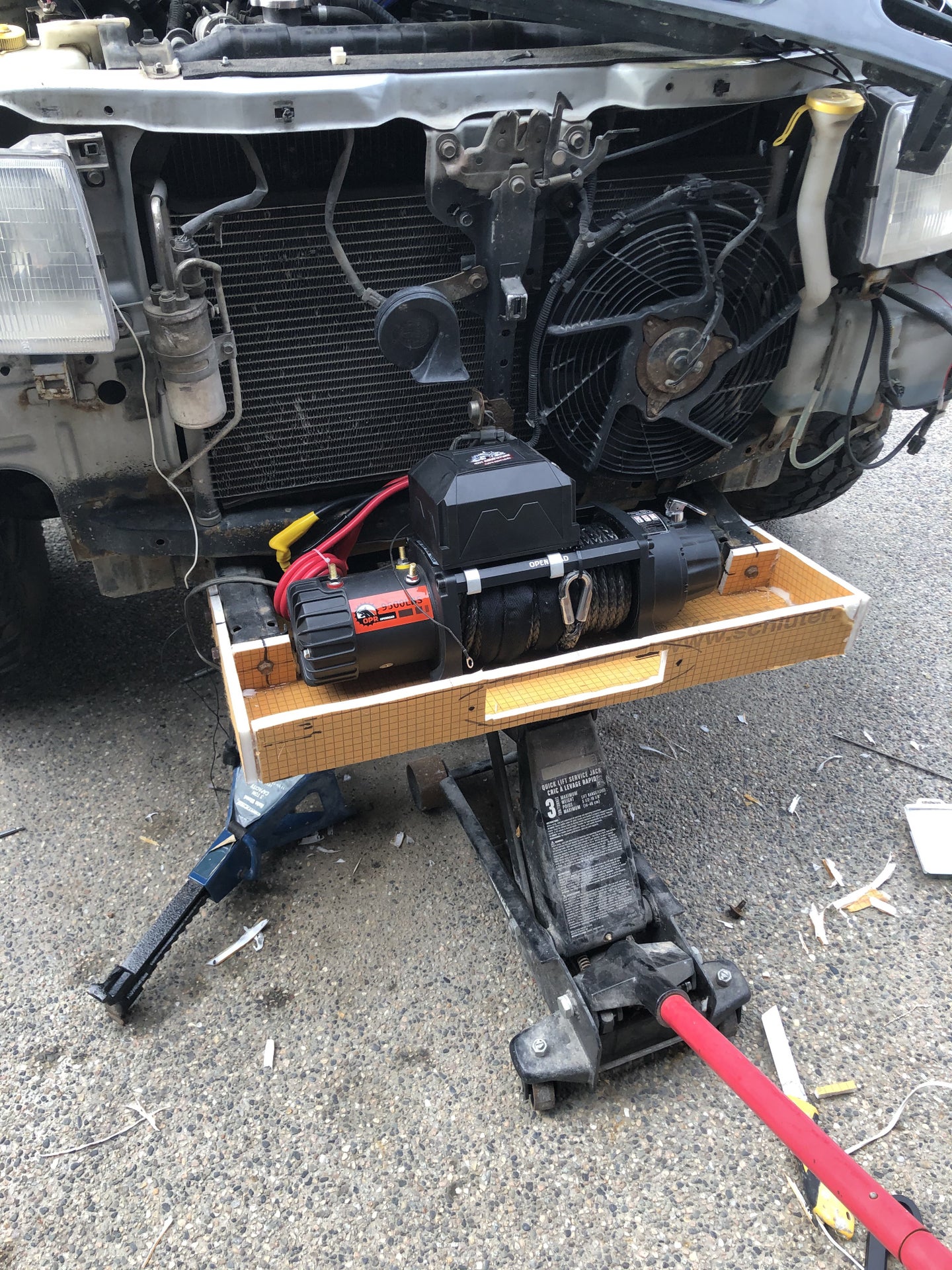

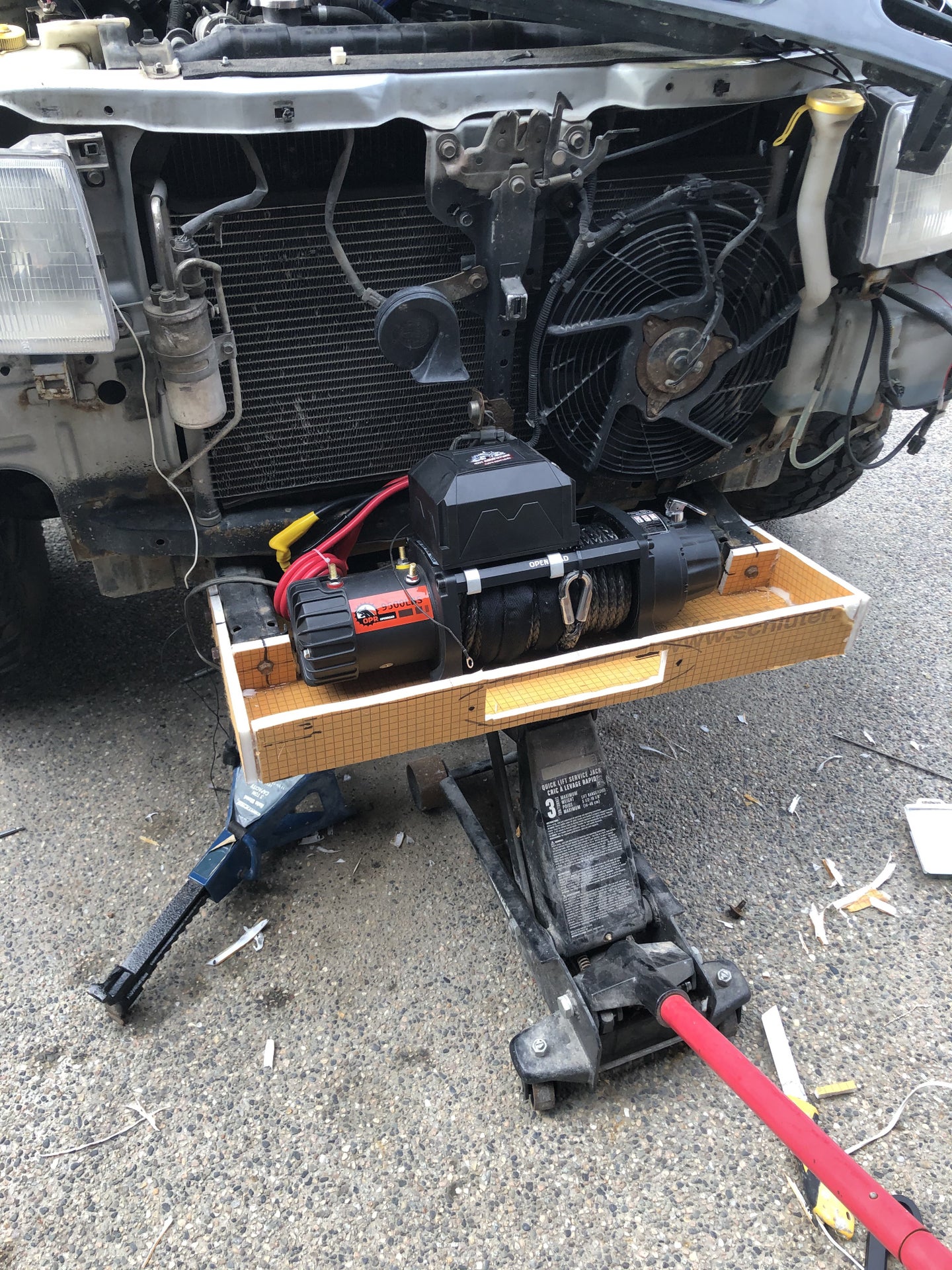

the mounting process was easiest with a Jack to fit it right. The steel on the sides was a bit warped when I bought it and I made the tolerances super tight so i had to pound on it pretty hard for the initial fitment. I had to make sure that the control box on top didn’t come in contact with the crash sensor. If you find another place to mount your control box you can tuck the winch further down the mount and make it shorter for a better approach angle. I didn’t want to find a place to put the control box so the front of the mount sticks out about an inch and a half past the stock bumper. I might change that in the future.

I used an epoxy roll cage paint I’m hoping it’s a cheap and relatively durable way to keep corrosion off. I’ll show a comparison of the stock font end and then the final result

the bumper is made out of a metal and plastic bumper and apron. With just the top part you get more tire clearance but it isn’t as clean looking.

I was debating on wether or not to put the plastic apron on because I would have to cut a section out, but it was already badly cracked and I didn’t want to store it somewhere so I figured what the heck. There is a curved section that looks like it was made for a winch to slot into. I cut that little piece out and here is the final result.

I’ve run out of attachments allowed for this I’ll show the approach angles from the side. Let me know what you think and how I can make it better

I didn’t have to drill any holes in the frame. I designed it in a way that it would bend underneath the frame horns and terminate at the factory tow hook mounting holes, working out the angles that the material needed to be bent too was difficult.

the idea is that most of the pressure from winching is directed up into the frame, instead of it being mounted on top of the frame horns. This also makes the design slightly more compact and lightweight.

I mentioned getting it fabricated at a shop. That didn’t work out, the shops I brought the design too took forever to get me a price. I assume they didn’t really want to do it; I don’t know if it was worth it to them to make it since I had done all the design work. But those are the fab shops in my area. I’m sure in different areas some shops might do it no problem. Almost every shop asked me to leave the template with them to get a price. Only two shops ever gave me a price, 600 dollars but those were aluminum specialty shops. And I wanted it made out of steel so they told me they would have to send it out to get it fabbed by a steel shop. So I went directly to steel shops, the others ended up taking half a week before they even took a look at it, and I would just ask for the template back because it was taking too long. The odd thing was the final shop I took it too, the guy took my template out of the shop for some reason, and it was like pulling teeth trying to get it back. I didn’t want to have to make another one. I decided to buy a welder and steel and fabricate it myself. The welder cost around $200 canadian for a 80 amp flux core welder From crappy tire. I have access to grinders drills bits wire and basic things to work on vehicles. Let’s say $150 in new tools, I used about $150 in steel 1/4 inch. I had never welded before. But I figured with enough research I would be able to. My welds aren’t pretty and the jury is still out on wether or not it’s strong enough we’ll see how it holds up. I bent the steel by cutting it over halfway, then locking a crescent wrench over it and levering the steel up. Then welded the cut side.

the mounting process was easiest with a Jack to fit it right. The steel on the sides was a bit warped when I bought it and I made the tolerances super tight so i had to pound on it pretty hard for the initial fitment. I had to make sure that the control box on top didn’t come in contact with the crash sensor. If you find another place to mount your control box you can tuck the winch further down the mount and make it shorter for a better approach angle. I didn’t want to find a place to put the control box so the front of the mount sticks out about an inch and a half past the stock bumper. I might change that in the future.

I used an epoxy roll cage paint I’m hoping it’s a cheap and relatively durable way to keep corrosion off. I’ll show a comparison of the stock font end and then the final result

the bumper is made out of a metal and plastic bumper and apron. With just the top part you get more tire clearance but it isn’t as clean looking.

I was debating on wether or not to put the plastic apron on because I would have to cut a section out, but it was already badly cracked and I didn’t want to store it somewhere so I figured what the heck. There is a curved section that looks like it was made for a winch to slot into. I cut that little piece out and here is the final result.

I’ve run out of attachments allowed for this I’ll show the approach angles from the side. Let me know what you think and how I can make it better

Last edited: