slantyshanty

Bought an X

- Location

- 'Merica (DFW)

About two years ago I had quite a bit of time on my hands and tried to design a LED light bar using the stock roof rack cross bar.

Here I am

It was a fun project and actually worked VERY well... for the short time I had it on the X. (I moved cross country very shortly after completion and the car movers broke the light bar. I didn't notice until after I signed for the X and they left unfortunately.) Anyway. The way I went about making the LED enclosures worked but there was a lot of leftover parts and could be MUCH easier. (My project was R&D really)

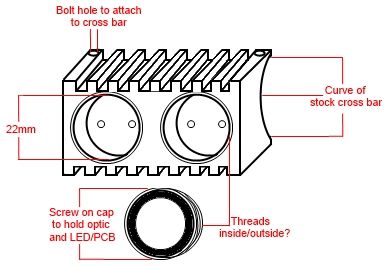

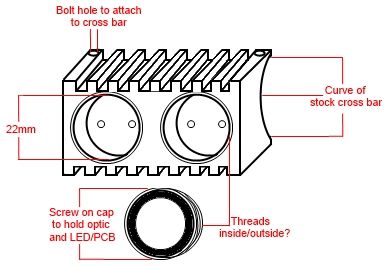

What I was thinking was making something anyone could use/install, that would be cheaper than buying one of the crazy expensive light bars that are out there, cheap enough that it wouldn't make you mad if you broke it, yet still give us X'ers an easily customizable option for LED lighting. I don't have any solid measurements other than the size of the LED PCB's that I used. (CREE XM-L T-6 22mm star PCB) No solid design parameters like heatsink fin size or optic size either... just an idea. Here's what I have so far:

-The rear curve would have to match the curve of the stock roof rack cross bar. Not sure how to go about measuring that?

-The threads for the cap... not sure if it would be better/easier/cheaper to mill to have the threads facing in (like the threads on a plastic coke bottle) But, if you did that, then the heatsink side could have to protrude and have it's threads on the outside. OR, have the threads on the cap face out, so the cap could be flush when screwed on (like the thing that holds your wheel bearings in, whatever it is called lol) Would be a cleaner look to be able to make it flush. The cap could essentially be a metal washer with threads on the outside edge.

-I didn't draw the fins on the side of the heatsink but I would think that the more the better. Those T-6's get pretty warm. Maybe not? If the curve of the heatsink matched the curve of the cross bar, you could completely heat goo between the heatsink and cross bar so it would/could transfer some heat to the cross bar itself... just a thought.

-Lastly, the heatsink itself could either be designed to hold the LED driver somehow, or just put the LED drivers inside the cab in their own enclosure somewhere/somehow. The drivers I was using COULD run 3 T-6's to almost full power. I had the mounted inside the cross bar and that really wasn't the "best" place for them. I would like to find new drivers for the LED's as well. The ones I used were high-low-strobe, with no memory. You had to turn them on and off to cycle through the modes. That was annoying, and illegal (strobe). If anyone out there knows people that make drivers, feel free to chime in. If these exist, I think it would be cool to have a 2 switch driver. One switch would be on/off, one switch would be strobe/off. Or one of those switches where the middle spot was off, up-on, down-strobe... or something like that.

The heatsink/driver combos could really come in any number. I drew two holes simply because that's how I had mine linked. I figured you could either have 1,2,or 3 LED's per heatsink, not 10 or something crazy. That way, if you only wanted/could afford a few at a time you could. So, the design would need to be easily stackable, or I think the word I'm looking for is modular? I think if you used two LED's, the whole heatsink wouldn't be more than 3"Wx2"Hx1"D'ish... maybe not even that big.

So,

How much would these heatsinks cost to get milled each?

Suggestions please!!!

(I smell an Xterra kickstarter)

If ya steal my idea, you just gotta give me a bunch of them for free

Here I am

It was a fun project and actually worked VERY well... for the short time I had it on the X. (I moved cross country very shortly after completion and the car movers broke the light bar. I didn't notice until after I signed for the X and they left unfortunately.) Anyway. The way I went about making the LED enclosures worked but there was a lot of leftover parts and could be MUCH easier. (My project was R&D really)

What I was thinking was making something anyone could use/install, that would be cheaper than buying one of the crazy expensive light bars that are out there, cheap enough that it wouldn't make you mad if you broke it, yet still give us X'ers an easily customizable option for LED lighting. I don't have any solid measurements other than the size of the LED PCB's that I used. (CREE XM-L T-6 22mm star PCB) No solid design parameters like heatsink fin size or optic size either... just an idea. Here's what I have so far:

-The rear curve would have to match the curve of the stock roof rack cross bar. Not sure how to go about measuring that?

-The threads for the cap... not sure if it would be better/easier/cheaper to mill to have the threads facing in (like the threads on a plastic coke bottle) But, if you did that, then the heatsink side could have to protrude and have it's threads on the outside. OR, have the threads on the cap face out, so the cap could be flush when screwed on (like the thing that holds your wheel bearings in, whatever it is called lol) Would be a cleaner look to be able to make it flush. The cap could essentially be a metal washer with threads on the outside edge.

-I didn't draw the fins on the side of the heatsink but I would think that the more the better. Those T-6's get pretty warm. Maybe not? If the curve of the heatsink matched the curve of the cross bar, you could completely heat goo between the heatsink and cross bar so it would/could transfer some heat to the cross bar itself... just a thought.

-Lastly, the heatsink itself could either be designed to hold the LED driver somehow, or just put the LED drivers inside the cab in their own enclosure somewhere/somehow. The drivers I was using COULD run 3 T-6's to almost full power. I had the mounted inside the cross bar and that really wasn't the "best" place for them. I would like to find new drivers for the LED's as well. The ones I used were high-low-strobe, with no memory. You had to turn them on and off to cycle through the modes. That was annoying, and illegal (strobe). If anyone out there knows people that make drivers, feel free to chime in. If these exist, I think it would be cool to have a 2 switch driver. One switch would be on/off, one switch would be strobe/off. Or one of those switches where the middle spot was off, up-on, down-strobe... or something like that.

The heatsink/driver combos could really come in any number. I drew two holes simply because that's how I had mine linked. I figured you could either have 1,2,or 3 LED's per heatsink, not 10 or something crazy. That way, if you only wanted/could afford a few at a time you could. So, the design would need to be easily stackable, or I think the word I'm looking for is modular? I think if you used two LED's, the whole heatsink wouldn't be more than 3"Wx2"Hx1"D'ish... maybe not even that big.

So,

How much would these heatsinks cost to get milled each?

Suggestions please!!!

(I smell an Xterra kickstarter)

If ya steal my idea, you just gotta give me a bunch of them for free