- Location

- Columbus OH

I know that I promised pics. but it is like 10 deg in my garage so that is not going to happen rite now.

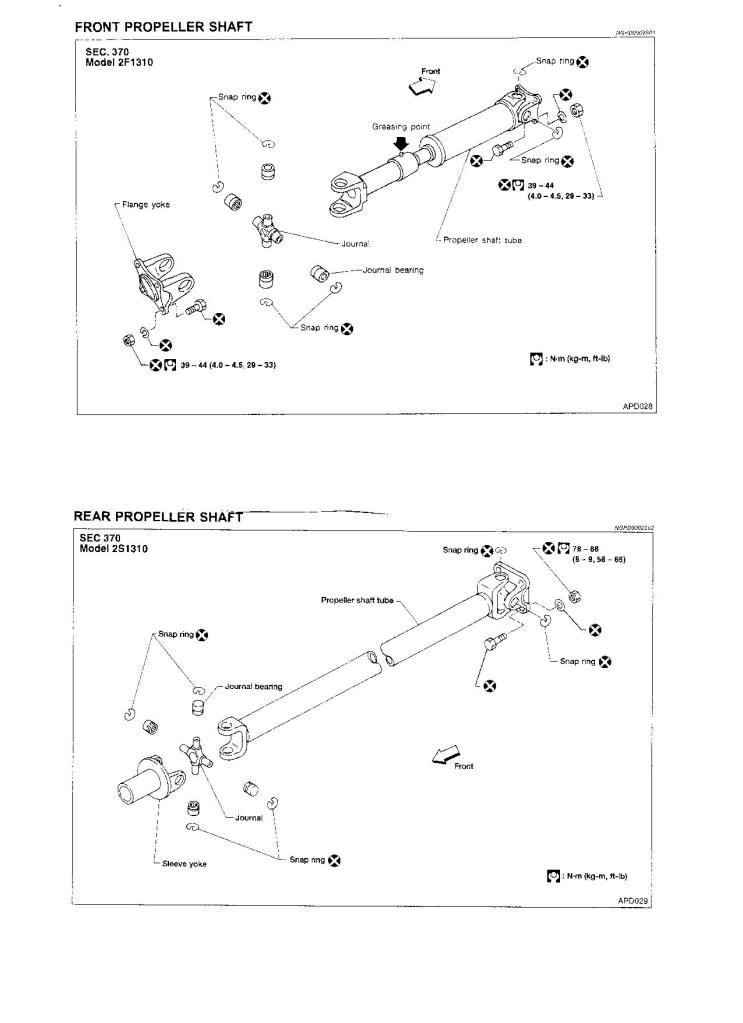

First step is to get a pair of spicer 1310 u-joints, and some red locktite.

Nissan does not view the joints an the Xterra as a servisable item so they do not list a part number, that being the case most parts stores can not look up there parts numbers.

Just tell them that it is for a 03 frontier and you will be fine (chevy used this same joint in the front of 1/2 ton pickups for an eternity so they will always have one or two on hand.

After you have the joints park on a hard flat serface and chok the front wheels.

jack up the rear end and place it on jack stands, and put the transmission in nutral.

To remove the drive shaft you will need a 8mm six point socket, a 3/8 impact is a great thing to have here.

Once you remove the straps on the end of the driveshaft, you need to push the shaft forward to get it out of the yoke. Sometimes a long prybar is enough, but it usually takes a sharp smack from a hammer to release any rust weld holding it all together.

When the DS is out of the truck remove the c-clips that are holding the u-joints in place.

There are three main ways to get the old joints out.

1 u-joint press(looks like a big C-Clamp with a hole at one end)

2 A shop press 12-10 ton

3 Deep well socket and big hammer

Drive the joint all 9of the way in one dirrection, so that you can remove tne bearing cap on one side so that you have room to get the joint out of the ear on the shaft. After the joint is out of one side repeate for the other three sides and inspect the ears for cracks or other damage, and make sure that the grooves for the c-clips are clean.

You had a choice between greasable and non greasable joints, if you got greasable pay attention to the dirrection of the zerks. If you put them in the wrong dirrectionyou will have two issues.

1 on the rear position you will not be able to get to the zerks to put the grease in.

2 on the front joint, it will hit the inner portion of the shaft and will not have a complete range of motion.

When re-assembly starts I like to put one of the c-clips in and drive the new u-joint untill it touches the c-clip, then put in the other c-clip. Once the entire joint is in hit the ears with a hammer to spring it and releave the pressure, allowing it to move freeley.

When you go to put the DS back in be careful not to nick the output seal or you will be replacing it very soon as you will see a spot of ATF in the driveway under the spot where the DS exits the Transfer case.

When you put the very small bolts that hold the back end of the DS to the rear diff, put some red locktite on the threads and run them in. DO NOT over tighten these 4 bolts.

I usually reassemble at all of the way, and then take out one bolt at a time to do the locktite.

First step is to get a pair of spicer 1310 u-joints, and some red locktite.

Nissan does not view the joints an the Xterra as a servisable item so they do not list a part number, that being the case most parts stores can not look up there parts numbers.

Just tell them that it is for a 03 frontier and you will be fine (chevy used this same joint in the front of 1/2 ton pickups for an eternity so they will always have one or two on hand.

After you have the joints park on a hard flat serface and chok the front wheels.

jack up the rear end and place it on jack stands, and put the transmission in nutral.

To remove the drive shaft you will need a 8mm six point socket, a 3/8 impact is a great thing to have here.

Once you remove the straps on the end of the driveshaft, you need to push the shaft forward to get it out of the yoke. Sometimes a long prybar is enough, but it usually takes a sharp smack from a hammer to release any rust weld holding it all together.

When the DS is out of the truck remove the c-clips that are holding the u-joints in place.

There are three main ways to get the old joints out.

1 u-joint press(looks like a big C-Clamp with a hole at one end)

2 A shop press 12-10 ton

3 Deep well socket and big hammer

Drive the joint all 9of the way in one dirrection, so that you can remove tne bearing cap on one side so that you have room to get the joint out of the ear on the shaft. After the joint is out of one side repeate for the other three sides and inspect the ears for cracks or other damage, and make sure that the grooves for the c-clips are clean.

You had a choice between greasable and non greasable joints, if you got greasable pay attention to the dirrection of the zerks. If you put them in the wrong dirrectionyou will have two issues.

1 on the rear position you will not be able to get to the zerks to put the grease in.

2 on the front joint, it will hit the inner portion of the shaft and will not have a complete range of motion.

When re-assembly starts I like to put one of the c-clips in and drive the new u-joint untill it touches the c-clip, then put in the other c-clip. Once the entire joint is in hit the ears with a hammer to spring it and releave the pressure, allowing it to move freeley.

When you go to put the DS back in be careful not to nick the output seal or you will be replacing it very soon as you will see a spot of ATF in the driveway under the spot where the DS exits the Transfer case.

When you put the very small bolts that hold the back end of the DS to the rear diff, put some red locktite on the threads and run them in. DO NOT over tighten these 4 bolts.

I usually reassemble at all of the way, and then take out one bolt at a time to do the locktite.